Challenge

A solution for transporting and transferring heavy fixtures in a molding process.

Solution

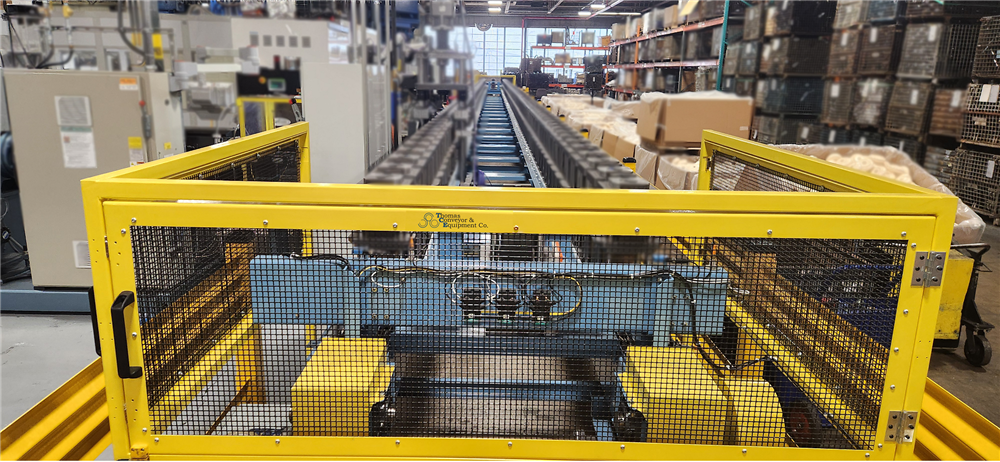

Our 2-Strand Chain Drag Conveyor with Servomotor Driven Pusher. Each conveyor line is 100 feet long with 2-strand #2080 roller chain with 5” chain strand centers, and roller chain attachments 12” on center. The chain is driven by a sprocket end drive with flange mounted bearings. The chain rides in Tivar chain guides on a formed channel frame. Fixed angle with UHMW contact the sides of the fixture to keep product square.

The roller chain attachments provide a pocket for the fixture to be conveyed for accurate product positioning. Also included is a proximity switch for chain attachment detection to guide product into position for the servomotor driven pusher bar transfer. Smooth product transfer is completed by a linear guided ball screw / servomotor driven cylinder with 39” net stroke. We provided barrier fences at the transfer areas with hinged access panels with door handle, and Keyence safety interlock.

A 2-strand chain drag conveyor is most commonly used to convey heavier loads, or pallets when the runner boards are running the hard way. This type of conveyor is available in multiple strands and strand centers.

The greatest benefit of this equipment is the direct drive with chain and sprocket allows the conveyor to pull very heavy loads smoothly in a controlled and consistent movement.

Results

This conveyor helps to automate the customer’s process, and queues fixtures into place for the operator to work on at station.

You would use this type of conveyor over a powered roller conveyor because product will coast on a roller conveyor, and its position will be less controlled. A slider bed belt conveyor would create too much friction and resistance and will be unlikely to work correctly. A plastic belt conveyor would be driven by plastic sprockets, and this would be sure to wear away quickly with these heavy loads.

We worked with the customer from the beginning stages of design all the way through delivery and installation. This customer has several lines (30 years old) that do the same operation, but the customer was most satisfied with the upgraded servomotor driven pusher and the smoothness of the product transfer. Transferring these fixtures has always been a challenge on the older conveyor lines with the older style transfers. The next project will be to replace the old transfers with the new upgraded servomotor driven pusher transfers on the customer’s other lines. These conveyors are extremely heavy duty and reliable with robust construction, and this is why we still see them running strong in the field over 30 years later.

This customer is extremely satisfied with the end result and wants to continue to do work with me. Please contact Thomas Conveyor and Equipment Company for all of your material handling needs at 708-449-2100. A project engineer is available to discuss your next project and provide project management from start to finish.